FMS Molding Analysis Ensures A Successful Mold Design

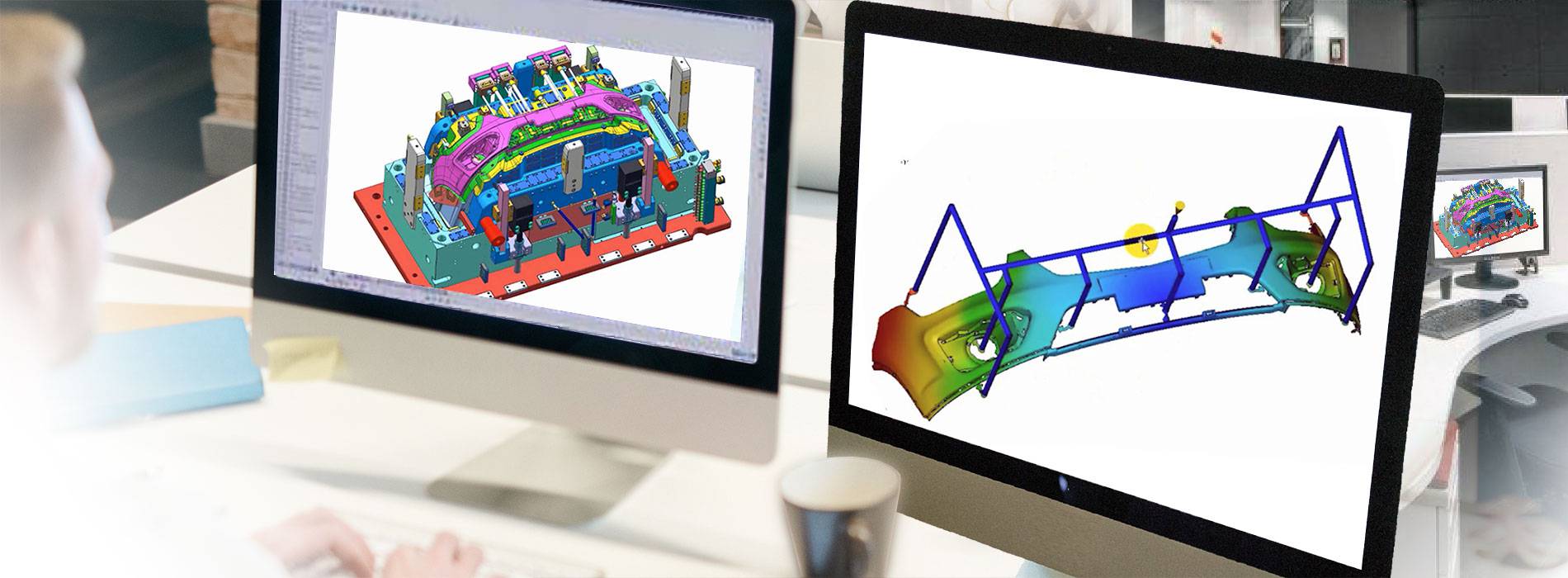

FMS molding analysis puts rich practical experience and profound expertise into our analysis system, rather than simple software operation. It can fully guide our mold design and predict what will happen to your mold, Of course, FMS molding analysis can also provide this kind of service to our customers individually if needed.

Collaborative Molding Analysis: Now we have implemented Collaborative molding analysis through the Internet. You can discuss our analysis online with us at any time, just as if we were working in your molding shop or engineering department or mold design department. Our customers are very satisfied

Our service is professional, efficient, integrity, good quality but not expensive.

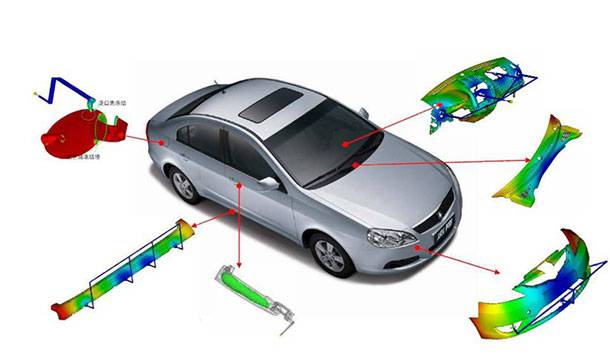

The engineers of First-rate Mold Solution Co. Ltd simulate the molten polymer of a complex injection molding by finite element analysis software. The data collected are used for explanation, forecast and

For instance, they use analysis module to simulate an injection flowing process, at first, our analysis software will give necessary advice to the engineer, as well as forecast flowing process of molten polymer in mold cavity. With these suggestions, our designer may make choice on the selection of material and assessment of molding condition, so as to help and optimize an injection molding process.

Flow simulation may determine optimal gate location(s) and optimized runner system, forecast weld line, determine the location of air trap, shear stress, filling time, filling possibility, mold clamping force, melt temperature, gate freezing time, pressure holding time and pressure. Application of CAE technology is becoming more and more important for First-rate Mold Solution Co. Ltd.

1)Flow analysis

Predict product filled if hysteresis, whether playing, filling is balanced, with lines and pack wind position, filling the required injection pressure / clamping force sizes, into the plastic location / number / size are reasonable.

2)Runner balance analysis

For a multi-cavity mold cavity or family, can be automatically balanced runner system analysis, through the analysis, we can recommend the flow channel dimensions, how much of the flow channel dimensions, several cavities filled at the same time, to achieve flow balance.

3)Gate location analysis

Moldflow gate location analysis which is called Gate location Analysis, whose role is to automatically analyze the best gate location. When the model already exists in one or more of the gate, and then manually set the gate already exists, the system will automatically analyze the best location for the other gate.

4)Cooling analysis

Prediction mold cooling water layout is reasonable, what areas need to be strengthened cooling, determine the thickness of product design is reasonable to predict molding cycles.

5)Warpage analysis

Predict product deformation and X, Y direction shrinkage values, combined with the adjustment of water / hold pressure parameters / methods into the plastic deformation and thus provide the smallest possible options before making the mold deformation

6)Shrinkage analysis

Analysis of the materials forming the product, the molding shrinkage fit put the number, and the volume contraction, if sink mark .

7)Gas-assisted analysis

Predict gas-assisted molding gas penetration distance, penetration effect, the best location and airway inlet arrangement to assess the product gas assisted molding shrinkage and deformation, etc.

Mold core offset forecast trends and offset by correcting the mold design, reduce the process of filling the core of the impact strength of the weak, extended tool life.

9)Stress Analysis

Predicted residual stress distribution molded product and size.

10) Fiber orientation Analysis

It is to analyze and control the fiber orientation of the plastic, injection-molded parts in order to reduce shrinkage, warpage , and the floating fibers.

Many different types of fibers, including glass fibers, carbon fibers, silicon carbide fibers, synthetic fibers, boron fibers and the like, the simulation can be based on different fibers we percentage simulation. Fibers can improve the material properties are as follows:

1、over time, reducing material plastic deformation occurs and stress relaxation

3、Improve the tensile strength

4、Improved heat distortion temperature

5、Improving the dimensional stability of the mixture

11) Overmolding analysis

Two-color molding molding products can be analyzed flows, warping and bonding situation.

12) Microchip Encapsulation IC chip package analysis

Predict chip package, thermosetting plastics in the mold cavity flow and curing conditions, flows on the impact of gold wire and pin

13) Underfill analysis

Optimization of thermosetting material molding conditions and filling dispensing model simulations predict various forms (I, L or … form) predicted injection pressure and clamping force of wind and demand forecasting package combines line position.

14) Birefringence Prediction

After forming the refractive index of refractive index difference can be manifested in the form tensor. General 0.1 The results for the optical parts is too large, it should be by adjusting the gate position, adjusting the process conditions or modify the product structure to achieve low residual stress. Asymmetric tensor indicate the occurrence of birefringence, the more serious the description of asymmetric birefringence more serious, actually see the “double word” the more obvious

Here I want to share something about my understanding in Moldflow Aanalysis:

1) Benefits of mold flow analysis

Mold flow analysis can offer various benefits for your injection molding projects, such as simulating the filling, packing, cooling, and warping stages of the molding cycle. It can also evaluate the effects of different material properties, mold geometry, gate location, and processing parameters on the final product. Moreover, it can identify and solve potential problems like short shots, air traps, sink marks, weld lines, and stress concentrations. Furthermore, it can optimize the mold design and layout, the runner system, the cooling channels, and the injection pressure and speed. Additionally, it can reduce trial-and-error iterations and material consumption while also enhancing the quality and consistency of molded parts.

2) Types of mold flow analysis tools

Depending on your needs and budget, there are various types of mold flow analysis tools you can choose from. Standalone software, for example, offers a comprehensive range of features and functions, but requires a high level of expertise and a significant investment. Cloud-based software, on the other hand, is an online platform that you can access through a web browser and use on demand. It offers a flexible and scalable solution, but depends on the internet connection and the security of the data. Additionally, plug-in software is an extension that can be integrated with your existing CAD or CAM software. It provides a convenient and compatible option, but has limited capabilities and compatibility issues. Finally, service providers offer mold flow analysis as a service either on-site or remotely. While they have a team of experts and advanced equipment, they also charge a fee and have less control over the process.

3) Features of mold flow analysis tools

When selecting a mold flow analysis tool, you should consider features that can improve the quality and efficiency of your analysis. Meshing, which is the process of dividing the mold and the part into small elements, should be able to generate a high-quality and accurate mesh, either manually or automatically, and handle complex shapes and geometries. The material database should have data on the physical and thermal properties of different materials and allow you to add custom materials. The tool should have multiple analysis modes, such as fill, pack, cool, warp, shrinkage, stress, etc., that can be performed sequentially or simultaneously with different injection molding techniques. Visualization should provide clear and detailed output such as 2D or 3D plots, animations, charts, tables, etc., and allow for customization of the output. Optimization should be able to find optimal values of the design and process variables to improve the performance of the molding system.

4) Methods of mold flow analysis

When performing a mold flow analysis, you should follow best practices and methods that can ensure accuracy and reliability of your results. This includes defining objectives and criteria, preparing data and model according to the tool’s specifications, running and verifying the simulation, and analyzing and optimizing results. Before starting the analysis, you should clearly define what you want to achieve and how you will measure it. When setting up the simulation, you should convert your CAD file to a compatible format and define boundary conditions. After running the simulation, you should check if it is valid and realistic and run multiple simulations with different scenarios or parameters for comparison. After obtaining results, analyze them to identify strengths and weaknesses of your molding system. Finally, optimize your results by adjusting or modifying design or process variables for improved performance.

5) Tips and tricks for mold flow analysis

To make the most of your mold flow analysis, you should consider tips and tricks that can help save time and money. For example, using a simplified model with only essential features and details, or a symmetrical model that only represents half or a quarter of your mold and part. Additionally, using a representative model to capture the behavior of your entire molding system, or a reliable tool that has been tested and validated by other users or experts. All these measures can help ensure the quality and accuracy of your simulation.

Mold analysis is the evaluation, revision, and validation of a mold to ensure it can produce a plastic part correctly the first time.

As a material, plastic has a certain charm: it’s lightweight, inexpensive and can be molded into almost any design. But just wait until that first warped or blistered part emerges from the mold. Designing a part so it can be manufactured easily and efficiently is critical to your product’s success.

With moldflow, you can determine the feasibility of a design by performing a 3D thickness check to analyze your model’s geometry and fix basic issues before handing off to a mold design expert.

Mold Flow Analysis Can Save Your Plastic Injection Mold Design

One of the keys to a quality plastic injection molded part is an accurate mold – one that produces consistent pieces time and time again. So how is that accomplished? First, if you are not familiar with the components of an injection mold and how they work, take a look at this blog post: Components of An Injection Mold to brush up on the basics..

Taking your mold from good to great is as simple as testing it via Mold Flow Analysis (MFA). This software simulates your mold conditions before you open up your wallet to pay for tooling. The effect MFA has on the quality of the mold, the performance and appearance of your product makes it an indispensable component of any plastic injection molding design project. Note: MFA software is expensive, but the return on investment is substantial.

What is Mold Flow Analysis?

Mold flow analysis (MFA) software simulates the flow of plastic, which allows you to elevate part and mold design to create products of impeccable quality. Like other simulation software, MFA gives you a virtual sneak peek into how your material of choice will fill the mold’s cavities and offers a head’s up on potential problem spots. The benefit is obvious, right? Simulating the process digitally means you can make changes BEFORE A TOOL IS CUT. This one thing is a big cost savings, not to mention a time saver as well.

When Should Mold Flow Analysis be Used?

In case it wasn’t clear, MFA is conducted before tooling production launches. (It wouldn’t make much sense to use it afterward!) Using a selected gate location and material properties, the software is able to predict how the part will fill during molding. Different data points can be assessed, including pressure, fill time and melt temperature. Doing so allows for optimization of the process before tool manufacturing ever begins.

Is Analysis Necessary for Every Application?

The short answer: not necessarily. The following factors can help you decide whether MFA should be used for your application:

PRODUCT GEOMETRY

The more complex the product geometry, the more benefit you’ll receive from MFA. Why? When the product’s design is more intricate, the flow is less predictable. It’s easier to predict how a simple mold design would fill, for example.

TOLERANCE REQUIREMENTS

Tight tolerances are an anathema to plastic injection mold designers anyway. Software that can analyze and demonstrate whether a product will meet spec prior to cutting a tool is a godsend.

PROJECT SCOPE

Clearly a project would have to meet certain financial requirements to warrant the investment of resources — time, software and talent — to run the tests.

UNUSUAL MATERIALS

Engineers know the fill patterns of standard materials but others — especially materials that include fillers — benefit from up-front analysis.

Development of high-density packaging and miniaturization in electronics industry requires designers to design small, thin-walled high-performance connectors, this requires higher quality plastic products for insulating and fixing contacts. In order to improve quality of plastic products in connector, shorten processing cycle, quickly and efficiently occupy market, it is necessary to adopt advanced mold flow analysis technology. Before actual production, potential problems in product and mold design can be found, make improvements, so as to ensure that a qualified product can be produced after a trial. Computer-aided engineering (CAE) technology has become the most effective way for these weak links in plastic product development, mold design and product processing. Compared with traditional mold design, CAE technology has great advantages in terms of improving productivity, ensuring product quality, reducing costs and reducing labor intensity. Using CAE (Moldflow) technology can simulate and analyze entire injection molding process on a computer before mold processing, accurately predict filling, holding pressure, cooling conditions of melt, as well as stress distribution, molecular and fiber orientation distribution in product, shrinkage and warping deformation of product, so that designer can find problem as soon as possible, modify part and mold design in time, instead of waiting for trial mold to repair mold. This is not only a breakthrough in traditional mold design methods, but also has great technical and economic significance for reducing or even avoiding mold repairs and scraps, improving product quality and reducing costs.

Mold flow analysis is a technique that involves simulating an injection molding cycle with a specific type of plastic and then evaluating the results. Prior to injection molding, moldflow analysis is essential. It involves using specialized software to simulate the design of the component. This should happen. Because the liquid material flows inside the mold significantly impacts how the finished product behaves, this process can help save a lot of time and effort in the long run.

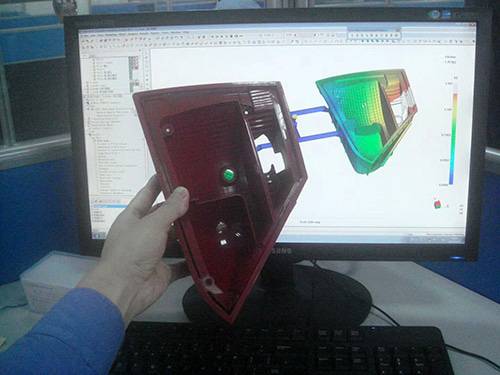

The software generates color maps mirroring design features as they appear in mold flow. It includes features like heating and/or cooling, fill pattern, injection pressure, potential air traps, shear stress, fiber orientation, and a variety of other features. Mold flow analysis is a meticulous and hands-on process reserved for professionals only.

Everyone agrees that quality parts come from a flawless mold, and digitally simulating the process is the key to starting out with flawless tooling. Moldflow, an MFA software company owned by Autodesk, is one of the leading companies providing software to improve injection molding designs.

Here are some of the benefits you can expect from their software:

Optimized gate locations: In the past, gates (those areas that control plastic flow to the cavities) were made smaller initially and then re-machined after sampling the part—a costly and time-consuming step.

Mold cavities that are filled uniformly and consistently

Ability to find visual defects: Air traps and sink marks are discovered and eliminated up front.

Wall thickness issues are resolved

Weaknesses in design can be corrected

Various materials can be evaluated before production

Improvements to the manufacturability of the part can be made

The time it takes to get your parts to market is reduced

Will your injection mold shop always use Moldflow?

Probably not. While a mold flow analysis can be helpful for most projects, it is especially beneficial where there is a part with complex geometry and intricacies that make it more difficult to predict flow. Similarly, in parts with tight tolerances, mold flow analysis will ensure that your parts meet the required specifications with the material and tooling design.

On the other hand, you need to be able to justify the cost of conducting the analysis. The size and scope of your project must be large enough to merit the cost and labor to run the MFA.

Mold Flow Analysis services are made available to clients, by some of our most experienced engineers and professionals, holding experience and skills in the domain. The mold flow analysis provided by us, includes Fusion, Flow, Cool and Warp. The analysis supports customer’s ability to provide the finest plastic parts, cost effective manufacturing, generating precise layouts and designs required and eliminate expensive process of trial & error.

Mold Flow Analysis include:

Fusion / Flow / Cool / Warp

Some of the advantages of these analysis procedures include:

Supporting customer’s demands of building better plastic parts featuring lower set up time as well as costs involved

Arriving at correct tool layout and runner designs required

Providing complete report which eliminates expensive process of trial & error

Allows achieving quality plastic injection molded parts at very first time

Achieving optimal weld line placement

Allows predicting short shots especially important for those involved in creating plastic parts

There are multiple benefits to Molding analysis. They include:

Resolution of wall thickness complications / Gate location optimization / Mold cavities fill consistently and uniformly / Discover defects in design geometry / Prevent expensive tooling errors and rework / Enhance manufacturability / Reduce time to market / Boost efficiency and quality / Reveals potential visual defects, including air traps, sink marks and weld lines / Assess different material options, pre-production / Provides data to support design changes

Mold-filling analysis is the computer simulation of molten plastic flow into a given mold geometry. This could be a plastic part, hot or cold runner, gate, nozzle tip, sprue, rib, etc. For a mold, the flow is predicted to the point of 99% filled; packing is a separate simulation. With proper application by an experienced user, this flow simulation can predict—before the mold is built—how the flow front progresses through the flow path of nozzle, sprue, runner, gate, and part. This allows for possible prediction of gate location, fill time, flow restrictions, plastic pressure distribution, air entrapment, venting issues, temperatures, weld lines, and other concerns associated with plastic part production.

Possible is emphasized here because analysis of a virtual process in the computer is sometimes accurate and sometimes not. The software continues to improve, and more advanced programs attempt to simulate packing, warpage, and cooling. This article will focus on only the filling or flow simulation aspects. My perspective on flow simulation is that it is a type of computer-aided engineering (CAE), with the emphasis on aided. The computer can’t do it alone. The software helps an experienced user determine the fill pattern and associated phenomena. Computer software does not have the magic capability to provide good results if the person using it has little or no experience with plastics materials, processing, and tooling.

Mold flow analysis simulation software is a valuable tool that aids in bringing quality parts to market on time and on budget. Simulation software is an essential tool in the development of complicated 3D part designs and also helps to predict the effects on quality of making existing products lighter and thinner. Although simulation software will not produce results with 100% accuracy it will stop you from making some huge mistakes.

Before mold production begins, our designers always use MoldFlow software to analyze the proposed mold design to ensure that the mold will be capable of producing the strongest, most uniform parts from each cavity. Using either a customer-supplied part design, a computer model of the mold is constructed. The Moldflow software then uses this model and the processing characteristics of the specified resin to predict how the resin will flow through the mold and into the cavities. This allows various key molding attributes, such as melt temperature, pressure profile or time-to-fill, to be studied and optimized “virtually” before the mold is built. Instead of being discovered during the initial mold trial, Moldflow points out potential tooling-related molding problems and allows them to be corrected prior to cutting steel. In this way, costly and time-consuming tooling rework is avoided.

MoldFlow is not used on every application. Based on the product geometry and tolerance requirements, our designer will make suggestions for the inclusion of flow analysis costs into the program. Working with the flow analysis service provider, our engineers provide real world inputs into the process to obtain the most accurate results.

Mold Flow Analysis by simulating the Die Casting Process and making a digital prototype. By doing that, we reduce the number of physical prototypes required to perfect a design and get your products to market faster.

Modlfow is pioneer in simulating and predicting flow behavior through a mold to help eliminate potential manufacturing problems, optimize part and mold designs. it pinpoint the severity and location of potential manufacturing defects such as weld lines, air traps & sink marks and then make necessary design changes to avoid these problems.

We simulate the filling phase of the molding process to predict the Die cast part melt flow pattern ensuring that mold cavities fill uniformly avoiding short molds, and eliminate, minimize or reposition weld lines and air traps. We optimize the overall packing profile and visualize the magnitude and distribution of volumetric shrinkage to minimize part warpage and eliminate defects such as sink marks & other visible defects.

Mold flow services include:

Moldflow analysis / Mold filling time / Injection molding analysis / Runner sizing analysis / Locating optimal gating positions

Go beyond validation to achieve true part optimization with fill, pack, cool and warp analyses. Moldflow helps you get perfect parts from the start by simulating the injection molding process in the design phase of your project. You can improve your mold’s performance and avoid costly manufacturing problems up front. A complete flow analysis delivers accurate results by combining moldflow with years of molding experience, processing expertise and our advanced hot runner technology. Think of it as an insurance policy for your molding project.

Mold flow analyses can optimize your overall cycle time by up to 10-30%. That reduction percentage on just one part can cancel out the cost of a complete flow analysis of multiple molded parts!

Ability to Select the Perfect Source

You can select the right source with expertise and practical experience for simulation, design, tooling, and molding. Otherwise, you would be spending money on analysis costs, as well as all tooling and molding issues, without obtaining any of the savings from upfront process simulation.

Specification

Plastic parts can be optimized for exact machine specification, cycle time, cooling, DOE, and more, without reducing production time or putting any tools on molding machines; this can help improve your bottom-line profit.

The predictive process of mold flow analysis can uncover design issues, save resources, provide for preemptive correction, and speed up overall cycle time and present your business with an abundance of benefits.

In a real service process, All analyses and simulations should be done in house by the same team of engineers, designers and processing experts who take care of you throughout the life of your project. This insures you get fast, accurate results and that your design optimization is streamlined, responsive and saves you money.

In the part or mold design phase of your project, the application engineers should explore with you all aspects of your process. Based on your specific molding requirements, this service team should run a fill, pack, cool and/or warp analysis and deliver your feedback in a detailed report outlining improvements and optimization. Nothing is outsourced and they should ensure that their turn-around is extremely fast so you can make your important decisions quickly and with confidence.

There are many benefits to using Modlfow during your injection molding and prototyping processes. Aside from improved manufacturability and reduced time to market, Moldflow can illustrate data to suppliers and customers to support your mold and part design.

Moldflow also reveals visual defects such as flow lines, sink marks, and potential air traps before constructing a part. Ultimately you can adjust a mold and perfect your process before creating a prototype or production tool, avoiding errors and reducing overall project costs.

The guidance and knowledge base of professional manufacturers and injection molders can assist you in developing the best tool and part design possible. Plastics experts review design, test, and mass produce parts for a range of industries and multitude of products. they are also capable of performing Moldflow in-house. If your considering the benefits regarding Moldflow reaching out to a professional to broaden your knowledge base and guide you through the software program can ultimately enhance your production efficiency and part quality.

Is Analysis Necessary for Every Application?

The short answer: not necessarily. The following factors can help you decide whether MFA should be used for your application:

PRODUCT GEOMETRY

The more complex the product geometry, the more benefit you’ll receive from MFA. Why? When the product’s design is more intricate, the flow is less predictable. It’s easier to predict how a simple mold design would fill, for example.

TOLERANCE REQUIREMENTS

Tight tolerances are an anathema to plastic injection mold designers anyway. Software that can analyse and demonstrate whether a product will meet spec prior to cutting a tool is a godsend.

PROJECT SCOPE

Clearly a project would have to meet certain financial requirements to warrant the investment of resources — time, software and talent — to run the tests.

UNUSUAL MATERIALS

Engineers know the fill patterns of standard materials but others — especially mate

Taking your mold from good to great is as simple as testing it via Mold Flow Analysis (MFA). This software simulates your mold conditions before you open up your wallet to pay for tooling. The effect MFA has on the quality of the mold, the performance and appearance of your product makes it an indispensable component of any plastic injection molding design project. Note: MFA software is expensive, but the return on investment is substantial.

What is Mold Flow Analysis?

Mold flow analysis (MFA) software simulates the flow of plastic, which allows you to elevate part and mold design to create products of impeccable quality. Like other simulation software, MFA gives you a virtual sneak peek into how your material of choice will fill the mold’s cavities and offers a head’s up on potential problem spots. The benefit is obvious, right? Simulating the process digitally means you can make changes BEFORE A TOOL IS CUT. This one thing is a big cost savings, not to mention a time saver as well.

When Should Mold Flow Analysis be Used?

In case it wasn’t clear, MFA is conducted before tooling production launches. (It wouldn’t make much sense to use it afterward!) Using a selected gate location and material properties, the software is able to predict how the part will fill during molding. Different data points can be assessed, including pressure, fill time and melt temperature. Doing so allows for optimization of the process before tool manufacturing ever begins.

Is Analysis Necessary for Every Application?

The short answer: not necessarily. The following factors can help you decide whether MFA should be used for your application:

PRODUCT GEOMETRY

The more complex the product geometry, the more benefit you’ll receive from MFA. Why? When the product’s design is more intricate, the flow is less predictable. It’s easier to predict how a simple mold design would fill, for example.

TOLERANCE REQUIREMENTS

Tight tolerances are an anathema to plastic injection mold designers anyway. Software that can analyse and demonstrate whether a product will meet spec prior to cutting a tool is a godsend.

PROJECT SCOPE

Clearly a project would have to meet certain financial requirements to warrant the investment of resources — time, software and talent — to run the tests.

UNUSUAL MATERIALS

Engineers know the fill patterns of standard materials but others — especially materials that include fillers — benefit from up-front analysis.

The main reason to complete a mold flow analysis is the ability to predict where the current mold will have complications and offer a visual representation of where to focus resources to create fast, efficient, and consistent injection molded parts.

These are results that you can expect after an analysis identifies all areas needed for improvement:

Faster cycle times – You can expect your mold to run faster as it will be able to fill the parts quicker and more consistently after an anlysis that optimizes the injection molding process.

Reduce clamp tonnage – An optimized mold will reduce all restrictions and require only a miminum clamp load to secure the mold closed during the injection process.

Produce better quality parts – Your mold will offer consistency from part to part, whether that runs in the hundreds or millions. A properly designed mold will yield very minimal variance.

Speed up overall project progress – A mold flow analysis takes the guess work out of optimization and offers your tooling maker the resulting design that requires little to no modification to make optimized parts. Development time it minimized, which will also save you investment cost.

Reduce the number of mold test cycles – In early years of injection molding, development could take months to find the optimum design through trial and error. A computerized analysis removes most or all of the trial time, and allows the first use of the tool to produce optimized parts.

Reduce your delivery time on parts – An optimized mold will be ready to produce production parts sooner than ever before. As analysis modeling and software continually become better at creating accurate models, molds require less design and tooling changes before production can begin.

A good mold flow analysis has lots of benefits, although it is time consuming, the cost is much lower than the cost of trials during nights and days on a production injection molding machine. The difficulty is not to produce colored pictures but to explain to the customers the different results, some customers have enough knowledge to understand some others no.

In 90% of cases, I work before the injection mold is cut, so I am ready to take the responsibility of cycle time, warpage, sink marks and so others issues. I am specialized in gas assisted injection molding and I assist Chinese companies to produce plastic parts for the German automotive industry which generally use overflow. With short shot process, we can obtain a production costs reduction of 20% by simulation and 30% in practice

The consumer product development process is much more complex than just creating a design and having a machine spit out material in a desired shape; plastics are not as inert as they seem and do not operate like static building blocks. The color maps created by mold flow analysis assist in adaptive changes of the design in order to create a quality product before the molding process actually occurs. This ensures that when a prototype or product goes into production, it is going to perform and behave optimally. Despite the overhead that it adds to the process, mold flow analysis more than makes up for this in terms of final quality. In fact, it has been considered a factor in keeping North American manufacturing competitive in the face of cheaper product development processes elsewhere. Furthermore, it demonstrates a commitment to quality, and is a good indicator of design and engineering firms who are competent, reliable, and produce quality solutions.

A mould with a more complex shape will likely benefit from moldflow analysis because the flow is less predictable than with a simpler shape. The current trend is to make products lighter & thinner to save material cost but this makes moulding quality parts more difficult. The ability to optimise the gate location can prove essential for some parts with more complicated geometries.Moldflow analysis

Changes to the part design and also the tool design can be investigated and confirmed based on the moldflow output and potential quality issues in the part such as deep under cuts or inadequate draft angles can then be altered immediately to address these issues with little time and cost.we got much benefits from using moldflow analysis.

The advantages of moldflow are many, and the ability to see how a manufacturing process will work before financial outlay has been committed to tooling is priceless.

during mold design, we regularly use moldflow analysis so that new part designs can be analysed immediately for manufacturability. This includes not just the ability to mould a part, but also the quality of the resulting part, both physically and aesthetically. Moldflow

In the past there was a risk that flaws in part designs would not be noticed until a mould tool was made. Creating a virtual version through moldflow analysis, means multiple trials can be avoided and time and money saved, as changes in part and mould design at this stage would be far more

Mold flow analysis helps to maximize resources and create efficient products. It improves the entire injection molding process and cannot be ignored if durable products are the goal of the molding process. Therefore, this article talked about mold flow analysis in terms of how it works, it’s benefits, and how it can improve your design. From the article, it is evident that mold flow analysis is an important process in injection molding. Therefore, designers must incorporate it in their procedure to get the best result.

Molding flow analysis helps to examine mold design thoroughly. It is pre-analysis of the product manufacturing process with the help of software. Molding flow tries to come to a pre-conclusion of the temperature required to melt the plastics or steel, of the amount required to fill in the cavity and deciding the wall thickness of the object. For example, if due to any reason the wall of the object is too thick it would not cool properly and there would be sink marks that will not look good.

Molding flow analysis is a pre-manufacturing process which not only reduces the cost, it saves the time of the organization and it helps to manufacture parts, objects in a successful way. Suppose without a flow analysis if a prototype is manufactured and it shows some fault, then it needs to be started all again. The design of the tool needs to be changed and there would be enormous wastage of time and energy. Therefore, to control all these mishappenings a molding flow analysis is done.

A company expert in a technique of mold, injection considers flow analysis a necessary pre-requisite. There are various manufacturing companies which are an expert in 3D designing of objects and they are also an expert in designing tool according to the desired wishes. That is why some mold companies can supply the parts in all over the world especially North America and Europe.

Now, coming again to the molding flow analysis, it examines the flow of melted metal or plastic through channels and tells the quantity to be added or to reduce before manufacturing the parts. It is easy to cut the metal scrap from the object, but it is very hard to add metals due to their characteristics into the parts. For that, a whole new design is carved for the tool which overruns the manufacturing cost and time. All these problems can be averted through proper mold flow analysis.

Injection molding is altogether an expert technique which requires technical knowledge and years of experience in the field. China injection molding industry is considered such an expert especially in plastic injection molds and it is aptly called as an injection molding hub. It supplies, parts being used in healthcare equipment, automotive, electronics and home appliances. Almost everything is being manufactured in countries of this region through injection molding.

Injection molding has made the process of manufacturing an easy task compared to earlier days where the heavy objects were manufactured in one go and where the technologies like flow analysis were not common. Injection molding has turned the pace of economy in a great way.

In the case of plastic injection molding processes, simulations can also save considerable costs and, above all, time. Even in the initial phase of a project, professional simulation solutions help to determine the feasibility of specific designs. Or they help, for example, to determine the most suitable machines for injection molding. In addition, the software solutions can be used to design molds and determine the optimum process parameters – long before the first real component is produced.

Many injection molding defects occur during the filling phase. It is not uncommon for weld lines or voids or air inclusions to occur. Shrinkage and warpage of the components outside the tolerance limits lead to component rejects. This means that time-consuming and costly rework of the mold is necessary. Injection molding simulations are designed to predict these very defects. They identify problems that can occur and enable quick and easy testing with other parameters or part geometries. And they do this during the development phase, when changes can still be implemented easily and cost-effectively.

This is because the component properties are precisely displayed on the monitor as simulation results long before they can be measured in reality. Sophisticated injection molding simulation can also determine the orientations of different fiber-reinforced plastics and predict weak points in the component. For the mold manufacturer and the component designer, the precise data from the simulation make their work much easier. Thanks to them, time-consuming trial-and-error procedures are a thing of the past. Correction loops are significantly reduced.

For computer simulations to work and deliver realistic results, the computers first need a lot of input. If input data is missing as a basis for process calculation, or if it is inaccurate or even wrong, the injection molding simulation can also only output inaccurate results. The same can happen if the model to be calculated has been simplified so much on the computer that it does not reflect reality.

Highly professional injection molding simulation programs therefore contain extensive databases derived from countless measurements. Above all, this includes up-to-date material data, which have a considerable influence on the results of the simulation. The continuous updating of highly developed simulation software and the use of the latest program version enable precise component prediction.

Mold flow analysis is the process of simulating an injection molding cycle with a particular plastic and analyzing the results. Mold flow analysis should occur before the injection molding process ever begins, through the use of specialized software that simulates the design of the part to be manufactured. Since the flow of the liquid material in the mold makes a massive difference to the behavior of the product, this step can save a great deal of effort down the road. This software creates color maps of different properties of the design as they would be reflected in the actual mold flow. These may include heating/cooling, fill pattern, injection pressure, potential air traps, shear stress, fiber orientation, and many more properties. Mold flow analysis is a careful, hands-on-process meant for experts.

Here are our top seven reasons why you should always perform a mold flow analysis:

Optimization of Design

Without any tooling or molding necessary, you can answer all the what-if questions ahead of time. Mold flow analysis can point out many concerns or production factors, including:

Material selection issues / Thickness/thinness problems / Structural concerns / Weld line controls / Residual or structural stress issues / Filling concerns / Product function requirements / Sink or appearance problems, and more / Quick & Immediate Decisions

With mold flow analyses, you can make immediate, informed decisions. These decisions can impact multiple areas of the process including:

Product design

Material and process selection / Tooling

And everything else that is central to your production process

There’s no trial and error involved; there are just proven scientific engineering answers from art to part.

Optimization of Injection Molds and Tooling

You have all the information and answers to make the most optimal choices in injection molds and tooling to create the perfect product. Mold flow analysis can show you everything you need:

The optimal gate locations / Balanced filling and packing / Cavity layout / Mitigation of short-shot molding issues / Optimal injection mold materials / Prototype and production tooling / The best cooling layouts / Structural and thermal analyses for tool life / Core pull/deflection issues / Reasons for tool failures / Engineering calculations of pressure or force necessary for each part Etc…

Trying Different Materials

You’re now able to test out different materials and designs without building any prototype parts or tools. You can get virtual parts with a simulation as well, so you can have full process simulation with minimal upfront investment.

Optimize Overall Cycle Time

Mold flow analyses can optimize your overall cycle time by up to 10-30%. That reduction percentage on just one part can cancel out the cost of a complete flow analysis of multiple molded parts!

Ability to Select the Perfect Source

You can select the right source with expertise and practical experience for simulation, design, tooling, and molding. Otherwise, you would be spending money on analysis costs, as well as all tooling and molding issues, without obtaining any of the savings from upfront process simulation.

Specification

Plastic parts can be optimized for exact machine specification, cycle time, cooling, DOE, and more, without reducing production time or putting any tools on molding machines; this can help improve your bottom-line profit.

Creating a high performing mold is a vital part of the injection molding process, but can be a challenging. While one might think liquid plastic simply takes on the shape of the mold it’s injected into, a strong initial design and innovative techniques are vital to consistent part production.

Today, many manufacturers have proven mold flow analysis (MFA) to be the medium between a flawless design and production. Vital to the injection molding process, investing in MFA software will enhance mold quality, product appearance, and final performance. The return on investment more than justifies the cost of the MFA software.

Plastic parts can be optimized for exact machine specification, cycle time, cooling, DOE, and more, without reducing production time or putting any tools on molding machines; this can help improve your bottom-line profit.

The predictive process of mold flow analysis can uncover design issues, save resources, provide for preemptive correction, and speed up overall cycle time and present your business with an abundance of benefits. add mold flow analysis to your production as a way to improve the simplicity and quality of your final products.

Mold flow analysis (MFA) software simulates the flow of plastic, which allows you to elevate part and mold design to create products of impeccable quality. Like other simulation software, MFA gives you a virtual sneak peek into how your material of choice will fill the mold’s cavities and offers a head’s up on potential problem spots. The benefit is obvious, right? Simulating the process digitally means you can make changes BEFORE A TOOL IS CUT. This one thing is a big cost savings, not to mention a time saver as well.

The consumer product development process is much more complex than just creating a design and having a machine spit out material in a desired shape; plastics are not as inert as they seem and do not operate like static building blocks. The color maps created by mold flow analysis assist in adaptive changes of the design in order to create a quality product before the molding process actually occurs. This ensures that when a prototype or product goes into production, it is going to perform and behave optimally. Despite the overhead that it adds to the process, mold flow analysis more than makes up for this in terms of final quality. In fact, it has been considered a factor in keeping a mold manufacturing competitive in the face of cheaper product development processes elsewhere. Furthermore, it demonstrates a commitment to quality, and is a good indicator of design and engineering firms who are competent, reliable, and produce quality solutions.

actually in every molding analysis, In order to acquire the best filling time, Mold trial is made by setting different injection time, or Mold flow software is used to analyze data recorded by computer. Whether doing successive trials or being simulated point by point, is very tedious. A new method is put forward-seeking the minimum of curve being simulated by Lagrange interpolation. The minimum of the curve is the best filling time. This method can improve the efficiency of the simulation analysis. The software Mold flow provides the possibility to simulate the flow processes of plastic air intake manifold with different gate location and number of injection mold and to predict the position of air traps and weld lines. The location and number of the gate in injection mold are determined by comparing analysis results and avoid mold adjustment and mold repairing. Finished injection mold of plastic air intake manifold on basis of simulation is perfect.

molding analysis software allows manufacturers to create virtual simulations depicting how plastic will flow into a mold. This program can determine design flaws and mold complications before actual tool build begins. molding analysis software can test various mold designs and material selections in a virtual simulation. This can save you the time and materials needed to create a physical prototype. You’ll be able to eliminate imperfections and retest your product before cutting a production tool and ultimately save time, money, and resources.

It is optimal to utilize molding analysis software before starting the tooling production process. After designing and testing your mold through the software program, a virtual model of the initial design will be developed. Utilizing data and aware of mold qualities, molding analysis software will virtually predict how the material will flow through and fill the cavities of a mold.

With information regarding pressure, fill time, melt temperature, and other data points, one can analyze and adjust the mold accordingly, retest the improved model, and continue the process until a perfect mold simulation is created This software mitigates risk and error before production even begins.

There are multiple benefits to Molding analusis. They include:

Resolution of wall thickness complications

Gate location optimization

Mold cavities fill consistently and uniformly

Discover defects in design geometry

Prevent expensive tooling errors and rework

Enhance manufacturability

Reduce time to market

Boost efficiency and quality

Reveals potential visual defects, including air traps, sink marks and weld lines

Assess different material options, pre-production

Provides data to support design changes

In case it wasn’t clear, Molding analysis is conducted before tooling production launches. (It wouldn’t make much sense to use it afterward!) Using a selected gate location and material properties, the software is able to predict how the part will fill during molding. Different data points can be assessed, including pressure, fill time and melt temperature. Doing so allows for optimization of the process before tool manufacturing ever begins.

Molding analysis software simulates the flow of plastic, which allows you to elevate part and mold design to create products of impeccable quality. Like other simulation software, Molding analysis gives you a virtual sneak peek into how your material of choice will fill the mold’s cavities and offers a head’s up on potential problem spots. The benefit is obvious, right? Simulating the process digitally means you can make changes BEFORE A TOOL IS CUT. This one thing is a big cost savings, not to mention a time saver as well.

Molding analysis software allows manufacturers to create virtual simulations depicting how plastic will flow into a mold. This program can determine design flaws and mold complications before actual tool build begins. Molding analysis software can test various mold designs and material selections in a virtual simulation. This can save you the time and materials needed to create a physical prototype. You’ll be able to eliminate imperfections and retest your product before cutting a production tool and ultimately save time, money, and resources.

You can also utilize mold flow analyses to simulate a multitude of what-if scenarios. By creating a testing several different hypothetical mold designs you can ultimately produce higher quality products. Imagine the time it would take to adjust an actual mold for every design adjustment pre-production. With Molding analysis software testing mold design is a quick, innovative process that allows your team to ultimately save significant amounts of time and money.

It is optimal to utilize Molding analysis software before starting the tooling production process. After designing and testing your mold through the software program, a virtual model of the initial design will be developed. Utilizing data and aware of mold qualities, Molding analysis software will virtually predict how the material will flow through and fill the cavities of a mold.

With information regarding pressure, fill time, melt temperature, and other data points, one can analyze and adjust the mold accordingly, retest the improved model, and continue the process until a perfect mold simulation is created This software mitigates risk and error before production even begins.

Molding analysis analysis is the process of simulating an injection molding cycle with a particular plastic and analyzing the results. Mold flow analysis should occur before the injection molding process ever begins, through the use of specialized software that simulates the design of the part to be manufactured. Since the flow of the liquid material in the mold makes a massive difference to the behavior of the product, this step can save a great deal of effort down the road. This software creates color maps of different properties of the design as they would be reflected in the actual mold flow. These may include heating/cooling, fill pattern, injection pressure, potential air traps, shear stress, fiber orientation, and many more properties. Molding analysis is a careful, hands-on-process meant for experts.

When Should Mold Flow Analysis be Used? In case it wasn’t clear, MFA is conducted before tooling production launches. (It wouldn’t make much sense to use it afterward!) Using a selected gate location and material properties, the software is able to predict how the part will fill during molding. Different data points can be assessed, including pressure, fill time and melt temperature. Doing so allows for optimization of the process before tool manufacturing ever begins.

There are multiple benefits to Moldflow analysis. They include:

Resolution of wall thickness complications

Gate location optimization

Mold cavities fill consistently and uniformly

Discover defects in design geometry

Prevent expensive tooling errors and rework

Enhance manufacturability

Reduce time to market

Boost efficiency and quality

Reveals potential visual defects, including air traps, sink marks and weld lines

Assess different material options, pre-production

Provides data to support design changes

The consumer product development process is much more complex than just creating a design and having a machine spit out material in a desired shape; plastics are not as inert as they seem and do not operate like static building blocks. The color maps created by mold flow analysis assist in adaptive changes of the design in order to create a quality product before the molding process actually occurs. This ensures that when a prototype or product goes into production, it is going to perform and behave optimally. Despite the overhead that it adds to the process, mold flow analysis more than makes up for this in terms of final quality. In fact, it has been considered a factor in keeping North American manufacturing competitive in the face of cheaper product development processes elsewhere. Furthermore, it demonstrates a commitment to quality, and is a good indicator of design and engineering firms who are competent, reliable, and produce quality solutions.

Is Analysis Necessary for Every Application?

The short answer: not necessarily. The following factors can help you decide whether MFA should be used for your application:

PRODUCT GEOMETRY

The more complex the product geometry, the more benefit you’ll receive from MFA. Why? When the product’s design is more intricate, the flow is less predictable. It’s easier to predict how a simple mold design would fill, for example.

TOLERANCE REQUIREMENTS

Tight tolerances are an anathema to plastic injection mold designers anyway. Software that can analyse and demonstrate whether a product will meet spec prior to cutting a tool is a godsend.

PROJECT SCOPE

Clearly a project would have to meet certain financial requirements to warrant the investment of resources — time, software and talent — to run the tests.

UNUSUAL MATERIALS

Engineers know the fill patterns of standard materials but others — especially materials that include fillers — benefit from up-front analysis.

Today, mold flow analysis (MFA) software can simulate the flow of plastic through your proposed mold, allowing for enhancements to the mold design and producing high-quality parts—all before any machining is done on the tool! The MFA allows designers a look into the future, showing them how the plastic will fill the mold’s cavities and pointing out potential problems.

Everyone agrees that quality parts come from a flawless mold, and digitally simulating the process is the key to starting out with flawless tooling. Moldflow, an MFA software company owned by Autodesk, is one of the leading companies providing software to improve injection molding designs.

Here are some of the benefits you can expect from their software:

Optimized gate locations: In the past, gates (those areas that control plastic flow to the cavities) were made smaller initially and then re-machined after sampling the part—a costly and time-consuming step.

Mold cavities that are filled uniformly and consistently

Ability to find visual defects: Air traps and sink marks are discovered and eliminated up front.

Wall thickness issues are resolved

Weaknesses in design can be corrected

Various materials can be evaluated before production

Improvements to the manufacturability of the part can be made

The time it takes to get your parts to market is reduced

If you’ve had plastic parts manufactured in the past using traditional methods, you probably remember the process. You wouldn’t exactly call it hit-and-miss. The shop you worked with was reputable, and their team had the experience to take your part, design a mold, and produce samples for you to measure and test.

But despite the best efforts of everyone involved, your part came out of the initial mold trial with flaws. It may have been a visual defect, a wall thickness problem, or a design issue. It’s not surprising. With all of the variables that can affect the molding process, it isn’t easy to produce a perfect part on the first try.

Moldflow analysis simulation software is a valuable tool that aids in bringing quality parts to market on time and on budget. Simulation software is an essential tool in the development of complicated 3D part designs and also helps to predict the effects on quality of making existing products lighter and thinner. Although simulation software will not produce results with 100% accuracy it will stop you from making some huge mistakes.

Creating a high performing mold is a vital part of the injection molding process, but can be a challenging. While one might think liquid plastic simply takes on the shape of the mold it’s injected into, a strong initial design and innovative techniques are vital to consistent part production.

Today, many manufacturers have proven mold flow analysis (MFA) to be the medium between a flawless design and production. Vital to the injection molding process, investing in MFA software will enhance mold quality, product appearance, and final performance. The return on investment more than justifies the cost of the MFA software.

Designing a good injection-molded part is dependent on many factors. Proper flow of the resin into the mold is one of them. Moldflow is a proprietary software program that was created to digitally simulate flow of resin through your part geometry. The resulting data that emerges will essentially help you design a part that will mold better.

I am a professional moldflow engineer, Moldflow analysis can provide you following benefits:

Moldflow Filling Analysis / Optimize gating / Optimize runner system / Predict fill pattern / Predict injection pressure / Determine clamp tonnage / Predict temperatures / Visualize shear rate / Visualize shear stress / Determine fiber orientation / Predict volumetric shrinkage / Predict sink / Determine venting / Avoid air traps / Locate weld (knit) lines / Develop optimum ram-speed profile

Moldflow Cooling Analysis / Find hot spots / Calculate time to freeze / Visualize uneven cooling across core and cavity / Determine uneven cooling between core and cavity / Define required coolant flow rates /Measure pressure drop in cooling system / Determine (and reduce) cycle time / Optimize the cooling layout

Moldflow Packing Analysis / Calculate proper packing pressure / Define optimum packing profile

Moldflow Warpage Analysis / Predict warpage / Find cause of warpage / Determine warpage due to orientation ./ Predict warpage due to differential cooling / Understand warpage due to differential shrinkage

Moldflow Gas-Assist Analysis /Determine optimized gas channel layout / Predict gas penetration / See gas permeation / Predict skin/core ratio Establish required gas pressure / Define optimized gas pressure profile /Refine spillover design

Moldflow Co-Injection Analysis / Compute skin/core ratio / Calculate skin/core distribution / Establish switch over points for skin/core (A-B) / Establish switch over points skin/core/skin (A-B-A)

Moldflow is very important tool for verifying mold design and product design, I can say it is 99.9% helpful, mold flow analysis has lots of advantages and will save a lot of money.

A good moldflow analysis has lots of benefits, although it is time consuming, the cost is much lower than the cost of trials during nights and days on a production injection molding machine. The difficulty is not to produce colored pictures but to explain to the customers the different results, some customers have enough knowledge to understand some others no.

The consumer product development process is much more complex than just creating a design and having a machine spit out material in a desired shape; plastics are not as inert as they seem and do not operate like static building blocks. The color maps created by mold flow analysis assist in adaptive changes of the design in order to create a quality product before the molding process actually occurs. This ensures that when a prototype or product goes into production, it is going to perform and behave optimally. Despite the overhead that it adds to the process, mold flow analysis more than makes up for this in terms of final quality. In fact, it has been considered a factor in keeping North American manufacturing competitive in the face of cheaper product development processes elsewhere. Furthermore, it demonstrates a commitment to quality, and is a good indicator of design and engineering firms who are competent, reliable, and produce quality solutions.

Mold flow analysis is the process of simulating an injection molding cycle with a particular plastic and analyzing the results. Mold flow analysis should occur before the injection molding process ever begins, through the use of specialized software that simulates the design of the part to be manufactured. Since the flow of the liquid material in the mold makes a massive difference to the behavior of the product, this step can save a great deal of effort down the road. This software creates color maps of different properties of the design as they would be reflected in the actual mold flow. These may include heating/cooling, fill pattern, injection pressure, potential air traps, shear stress, fiber orientation, and many more properties. Mold flow analysis is a careful, hands-on-process meant for experts.

I am an injection mold designer, and MOLDFLOW’s help in our design is unquestionable. When designing a new mold, we can hardly design without its guidance.you can get full support for gating selection and optimized for size, type, location, layout, design etc, complete runner layout, runner balancing, full manifold layout, design, dimensions, pressure drop, heating control, and full details of shear heat, stress on flow, complete cooling layout optimization for hot spots, layout design, water line sizes, thermal pins, check different types of inserts, insert materials, different types of water control, coolant type verification, cooling cycle temperature control, flow, turburlent flow, balance, overall tower/water manifold control effects, solutions to existing cooling issues or tooling issues, overall clamping force calculation and optimization, vent locations, force calculations for your moving slides, lifters, core pulls, effects of unbalnced flow on tooling, stress calculations due to filling effects, tool life, tool stress failure, overall tooling design review of support bars, moving actions, ejection based on full understanding of effects of molding on the tool design and tool life.

I am a product designer, I think that moldflow is very helpful to us in plastic product design. for example, thickness, thick/thin section, material selection, structural issues, weld line/flow control, fiber orientation controls, models for full FEA analysis of molded parts, answers to many engineering changes, virtual parts without tooling and molding, verifiy different ribing, flow leaders, minimize gating, produce parts with least cost of tooling, lower machine tonnage, lower molding costs, and reduce overall product development costs.

I think moldflow is very good at the choice of materials for injection molding. If you are not sure about which plastics material to use, you can verify different grades of plastics materials, compare and verify for warpage, tooling, processing. You may be also able to compare some structural properties and use moldflow for complete structual analysis, part weight optimization, compare mateiral weight, costs, processing, tooling. Thus you can make a completely scientifically analyzed decision about materials.

I am an injection molding engineer, in my opinion, Moldflow can full Optimization of Injection Molding and processing set up – See complete list of molding isssues that can be resolved through moldflow analysis, just to name few gas traps, weld lines, flow marks, flow lines, gate blemishes, jetting, hot spots, burns, cold spots, under packing, over packing, short shots, temperature issues, filling issues, warpage issues, shrinkage issues, fiber orientation, strctural failure due to molding, material issues etc., complete reference molding tryout set up, full control over molding process and overall reduction in molding costs through optimized cooling time and cycle time can give you thousands of dollars in savings with just one analysis.

Moldflow analysis is automatically applied to almost percentage of parts where moldability issues are immediately present but flow analysis is also available upon request. And better yet, all in an effort to help our mold designer to design a better molds

Designing a good injection molded part depends on many factors. A suitable resin flow into the mold is one of them. Moldflow is a professional simulation analysis software that simulates the flow of resin through part geometry. The resulting data will essentially help you design a better mold.

3D simulation of injection molding greatly helps to mold design

To provide better analysis results of injection molding to guide mold designers, MOLDFLOW has become increasingly easy to operate

In fact, the molding analysis has been accepted by more and more mold designers

Actually, it depends on your mold project. If your mold project has a good quotation, this investment is necessary

Yes, moldflow is really expensive, and cost is an important factor when we invest in analytics software.

In fact, there are many Molding analysis software for us to choose. MOLDFLOW is not the only Molding analysis software.

Now moldflow can analyze more and more problems, it is really a good helper for our mold designers

I think it would be perfect if molding analysis software could do a real injection molding process, because there is still a gap between the present analysis and the actual results

With the development of Internet technology and artificial intelligence technology, moldflow analysis software will be integrated into intelligent die design system

Our moldflow analysis engineers often need to compare the results in the injection workshop to see if they are doing the correct molding analysis. This is very necessary.

no matter which kind of molding analysis software is used, actual work experience is very important, preferably in the workshop as a technician or even a worker.

Our company is planning to buy molding analysis software, and I highly recommend moldflow software.

But I still think moldflow is the best molding analysis software among them, and our mold engineers will agree with me.

In the field of molding analysis, there are many other kinds of molding analysis software.

But I have to say that moldflow software is very expensive. Our mold designers are increasingly relying on it.

Now moldflow is more and more powerful, and the analysis efficiency is getting higher and higher.

It is very important to understand and correctly use the final analysis report in running MOLDFLOW

As an injection engineer, I still think that modeflow analysis is very helpful to my work.

Modelflow analysis is very important, but it only provides references to mold designers.

The mold with the hot runner system must do moldflow analysis before deciding the structure.

I am a modelflow analysis engineer. I think the practical work experience of injection molding and mold design is very important for me to apply the moldflow analysis software correctly.

To be honest, moldflow analysis is very helpful to my mold design.

In my opinion, moldflow analysis is only a trend to analyze the injection molding, and then achieve the purpose of optimizing and guiding the mold design.

I think the mold with hot runner must be analyzed in moldflow before approving mold design

Even if you used to be an injection molding engineer, if you want to be an excellent moldflow engineer, you need to work hard to learn new things.

I agree with you very much. I find that our mold designers are more and more inseparable from moldflow.

The moldflow analysis report is very important when selecting the hot runner system for a mold.

Yes, yes, our mold designers often discuss mold design on moldflow. it is very helpful and avoid too much mistake

I think moldflow software is very easy to learn, but it is necessary to have rich experience in injection molding and professional knowledge in practice.

moldflow analysis engineers must have rich experience in injection molding.

Now MOLDFLOW analysis precision is higher and higher, it is more and more important for mold design

Now our mold designers are increasingly aware of the importance of MOLDFLOW report for their mold design.

As an excellent molding analysis engineer, we need very rich experience in injection molding and mould design.

As MOLDFLOW analysis technology becomes more and more mature, more and more mold companies choose to use molding analysis software to guide their mod design

MOLDFLOW analysis is becoming more and more important for many molds during injection mold design.

Our company’s products are under development now, many accessories need to be made of plastic, it seems that your moldflow analysis service is what we need, I will recommend your service to our manager next Monday.

In our company, we also have moldflow engineers. It is necessary for our both engineers to discuss the molding analysis.

in the future, molding analysis is more and more important for mold design

in plastic injection molding industry, molding analysis is very important for mold design, it can save money and time

For what is the best molding analysis tool, of course I recommend MOLDFLOW

it seems that your designers have very good understanding in injection molding

MOLDFLOW is a good analysis tool in molding analysis

Hі! it seems that your mold design idea is very good!

I recommend Moldflow for your molding analusis

molding analysis is a very important process for mold design and injection molding

Moldflow is our molding analysis tool, I recommend it

Hi now I have some plastic parts need to do molding analysis, could you help us to do?

of course, please send them to us by Email

I think Your understanding for the whole process of mould manufacturing is very good

Believe it or not, molding analysis is more and more important in injection mold design, I still recommend MOLDFLOW software

I still recommend MOLDFLOW

I still recommend MOLDFLOW as molding analysis tool

it seems that moldflow is your analysis tool!

now there are many kinds of molding analsis softwares in our market, but I still recommend moldflow software

I will recommend MOLDFLOW software to every molding engineer and mold designer, it is very good. please try it

I like to use Moldex3D,

molding analysis is more and more important for mold design

molding analysis is a very important process in mold design.

I think we can have a discussion between your company and our company after christmas holiday, maybe it is a good idea

Hi John

that’s a good idea, we are waiting for it

molding analysis is more and more important in mold design

this is an improtant process in mold design

moldflow is a very excellent molding analysis software

now there are many molding analysis software on our market

Excellent, what a website it is! This web site provides valuable information to us, keep it up.

you have a good mold design concept

no doubt molding analysis is more and more important, it seems that you understand it very well

POLYFLOW is recognized as the industry to solve complex non-newtonian rheological problems, including problems of viscoelastic flow CFD solver.

CAE technology has helped our mold design for many years!

Molding analysis is very important for injection mold design

after reading this introduction, it seems that your design concept in injection mold is correct

I like to use moldflow to do molding analysis

Your mold designers have a good understanding in mould design, because your team understand molding analysis process very well

there are many molding analysis software in our market, I prefer to choose Moldflow

it seems that we can do some projects together, we really need your service for our new products

Moldex3D is a global leading brand of CAE mold flow software in plastic injection molding industry

Moldflow is an excellent molding analysis software.

Very good info. maybe we can discuss.molding analysis is our main business

I am an injection molding engineer, molding analysis is also used in our process

your design process is very precise, because of using molding analysis technology

now molding analysis is more and more important in mold design and injection molding

molding analysis is more and more important in molding industry

Pretty! This is an extremely wonderful post.in my opinion, Many thanks for supplying these details.

molding analysis is a good helper for mold designers

Moldflow is a very professional molding analysis software, I love it.

I will try to suggest our mold engineers to work with you. maybe that is a good ideal

Thanks for your marvelous posting! I believe that your company can do a very good injection mould!

this article will remind many mould companies attache great importance to molding analysis

that is a very important job for mold design

This is a very professional job, you need to have some professional engineers

Our mold designers like to use MOLDFLOW when designing a new mould

molding analysis is really help us a lot in molud design

it seems that you know a lot about the importance of molding analysis

Very good process! it will help you a lot.We will be linking to this particularly great

post on our website. Keep up the great writing.

As a fresh mold engineer, I am very interested in molding analysis

Experience is the most important thing, then you can do it well.

Moldfolw is an excellent CAE software in plastic molding analysis

Our company is a professional molding analysis company, we can exchange experiences, even do it together.

Hi I desire to discuss molding analysis with every one who is interested in it. more professional guys would be better

I prefer to use Moldflow to do molding analysis

understanding every analysis result is very important

molding analysis guides our mould designers when they need help

Molding Analysis is very important, but Some mould companies ignore it’s importance

also we have molding analysis department, I admit it can help our design a lot

for molding analysis, the most important part is how to explain analysis result

molding analysis is more and more important in our mold company

it seems that you have some professional molding analysis engineers, it will be good for your customers

Our mold designers very envy you have a special molding analysis department

it seems that your company has an excellent molding analysis team

we use Moldflow software as molding analysis tool, it is very professional

molding analysis is very important for mold design

Our company has a molding analysis department to provide useful advices for our mould designers

a lot of mould engineers are not still good at using molding analysis

Molding Analysis is very important for mold design

I have to admit that molding analysis helps us a lot in our mold design

Our company’s emphasis on molding analysis is not enough

actually it is not easy to do a professioanl molding analysis

as a molding engineer, I agree that molding analysis is very important for mold design

Moldflow analysis simulation software is easy to operate, but the result’s analysis is very important

In multi-cavity mold design, molding analysis is especially important

many mould companies still ignore the importance of molding analysis

in our mold industry, molding analysis will become more and more important

Molding analysis makes our mould designers to avoid a lot of mistakes

Molding analysis give a great help to our mould designers, now they cannot leave it

Any molding analysis software is merely a tool, the key is your engineer’s technical level

I will recommend Autodesk Moldflow, It’s really professional