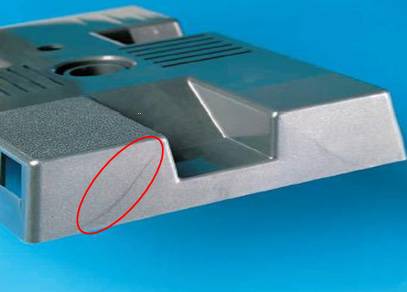

as an injection molding engineer, he should be very familiar with welding mark, the thread mark formed at the front confluence of two or more melt flows in the cavity is called welding mark or welding line. Usually, apart from low mechanical intensity, such defect as depression and aberration may also occur at places where welding mark appears.

For plasticparts with holes and inserts or those of complicated structure and with uneven wall thickness or those with overlarge structural dimension and requiring muti-gate feeding, plastic melt will form two or more flow filling in the cavity and the welding structure shall be unavoidably formed at the front confluence. The key index for measuring welding quality is the welding intensity at the welding mark, whereas the position of welding mark of which certain appearance quality is required follows in the second place. The most influential factor for welding intensity is the temperature during the confluence of melt.

Leave A Comment