Adverse factors of injection machine and product structure design are in the following:

1) The actual quantity of injection for the injection machine is too small and the melt required for filling is insufficient, thereby directly resulting in material shortage in the cavity.

2) The injection stroke of screw is ended and the plastic stocked in the plastication room is scarce, resulting in poor transmission of injection pressure and insufficient post-stage power of filling.

3) Injection rate of screw is excessively low, the injection pressure is overlow and the filling power is insufficient.

4) Wall thickness of products is uneven and the filling resistance is large.

5) Wall of products is too thin and the filling resistance is large, above all, temperature of melt drops too fast when it flows through

Slution:

1)Select proper injection machine and correctly adjust screw injection stroke to ensure sufficient actual quantity of injection, meanwhile, it should be ensured that the melt stored in the plastication room at the front of the screw can perfectly transmit pressure. Check the plastic raw material in the hopper of injection machine in due course to see whether it is sufficient。

2)Increase injection pressure, injection rate and the filling power of melt, meanwhile, check whether the non-return valve on the screw is damaged to avoid pressure caused by the counterflow of melt as well as loss of melt during injection.

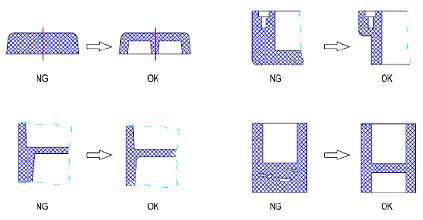

3)Improve structure of the plastic parts and dersign of wall thickness, reduce complication of structure, improve uniformity of wall thickness and properly design wall thickness to reduce structural resistance during the melt filling stroke.

I appreciate you can share your successful experiences with us , I have to share with more peoples, so that they can support you

You are very proficient in injection molding, Our company should consider to cooperate with you